Integrated Solutions. Proven Performance. Reliable Results.

Customer Perspectives

“Thanks to our partnership with Leica, we have access to instruments of the highest caliber. The whole approach is about the quality, traceability, and connectivity… It's a base to work on innovation and development relying on the know-how of the pathologist. We also want to develop other technologies associated with this basis. So, it can be digital pathology technologies based on artificial intelligence.”

Translated from source language.

Dr. Eric Peltier

Président Directeur Général - PRAXEA-DIAGNOSTICS

"Leica Biosystems products are reliable and high quality, and the company is realistic about what's required to transform traditional pathology to a digital, connected practice. I know I can count on them and trust they will be there to support me now and well into the future."

Translated from source language.

Dr. Sylvia L. Asa, MD, PhD

Consultant in Endocrine Pathology, University Hospitals Cleveland Medical Center

NEWS & PROMOTIONS

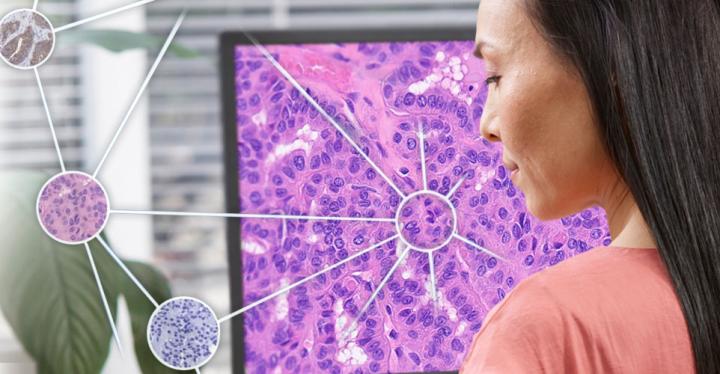

Leica Biosystems and Indica Labs Announce Significant Strategic Investment and Creation of Digital Pathology Platform

Combining leading hardware and software is expected to provide a compelling solution for digital pathology users across the full translational medicine paradigm, from early biomarker discovery to clinical trials, and through to routine diagnostics.

The Value of an RTU - Antibodies

Unlocking the benefits of an RTU antibody in your lab

Historically, ready-to-use (RTU) antibodies have been viewed as more expensive compared to concentrated antibodies. But what about hidden costs like technician and scientist time? In modern labs, where efficiency is key, RTUs offer undeniable value.

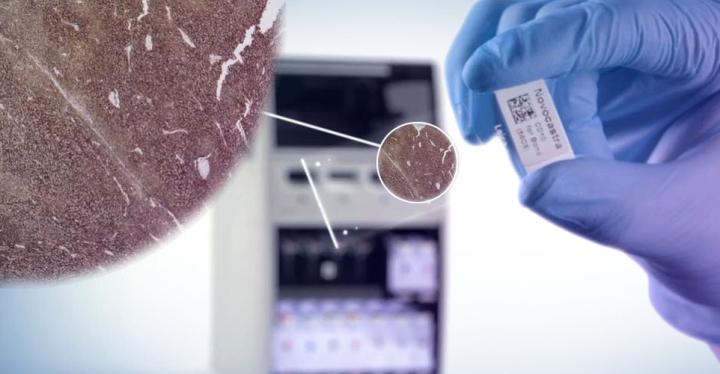

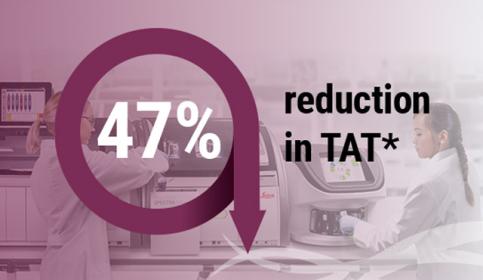

Improved turnaround time and precise digital scanning using glass coverslips

In a recent testimonial, an independent university pathology laboratory compared the slide drying times in a glass coverslipper vs a film coverslipper.

During the demonstration using the HistoCore SPECTRA CV Coverslipper, the customer experienced a 47% reduction in TAT*, reduced exposure to Xylene, and a standardized drying methodology.

Projections and Realized Results are specific to the institution where they were obtained and may not reflect the results achievable at other institutions.

*TAT= turnaround time from coverslipping until slide drying complete